Gap House

- Location

- Bristol, UK

- Client

- Bristol City Council

- Expertise

- Architecture

- Landscape Architecture

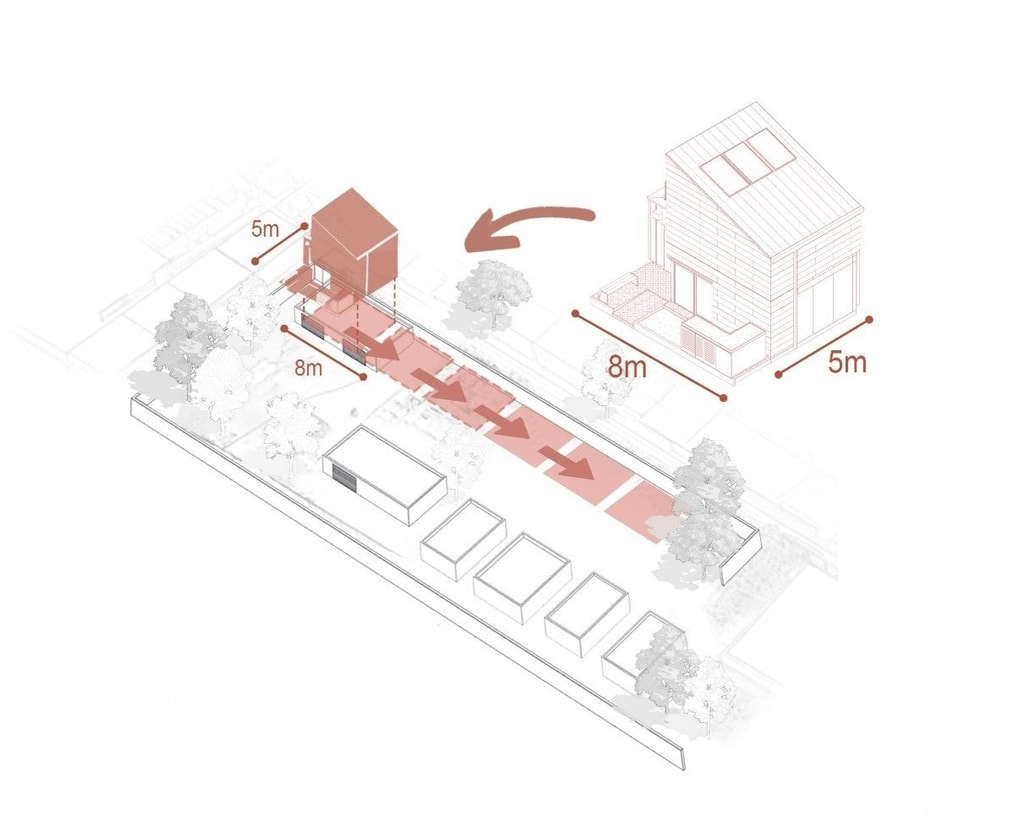

Factory constructed, contemporary and cost-effective eco-homes designed to fit into small urban spaces, such as garage plots, to address housing shortages.

.jpg?u=2025-08-15T08:58:56.813Z&w=640&q=90)

.jpg?u=2025-08-15T08:59:00.373Z&w=1280&q=90)

.jpg?u=2025-08-15T08:59:03.749Z&w=640&q=90)

.jpg?u=2025-08-15T08:59:18.252Z&w=1280&q=90)

.jpg?u=2025-08-15T08:59:06.655Z&w=1280&q=90)

.jpg?u=2025-08-15T08:59:14.824Z&w=1280&q=90)

.jpg?u=2025-08-15T08:59:11.766Z&w=1280&q=90)

.jpg?u=2025-08-19T12:00:32.870Z&w=1024&q=90)

The UK’s housing challenge isn’t just about numbers. It’s about innovation, adaptability, and sustainability. With growing pressure to deliver homes on constrained urban sites, concepts like Gap House at Bell Close are paving the way for a new approach to housing delivery. Gap House is a sustainable small site housing solution that has shown what’s possible, but the real story lies in the lessons it offers for the future of MMC, low-carbon housing.

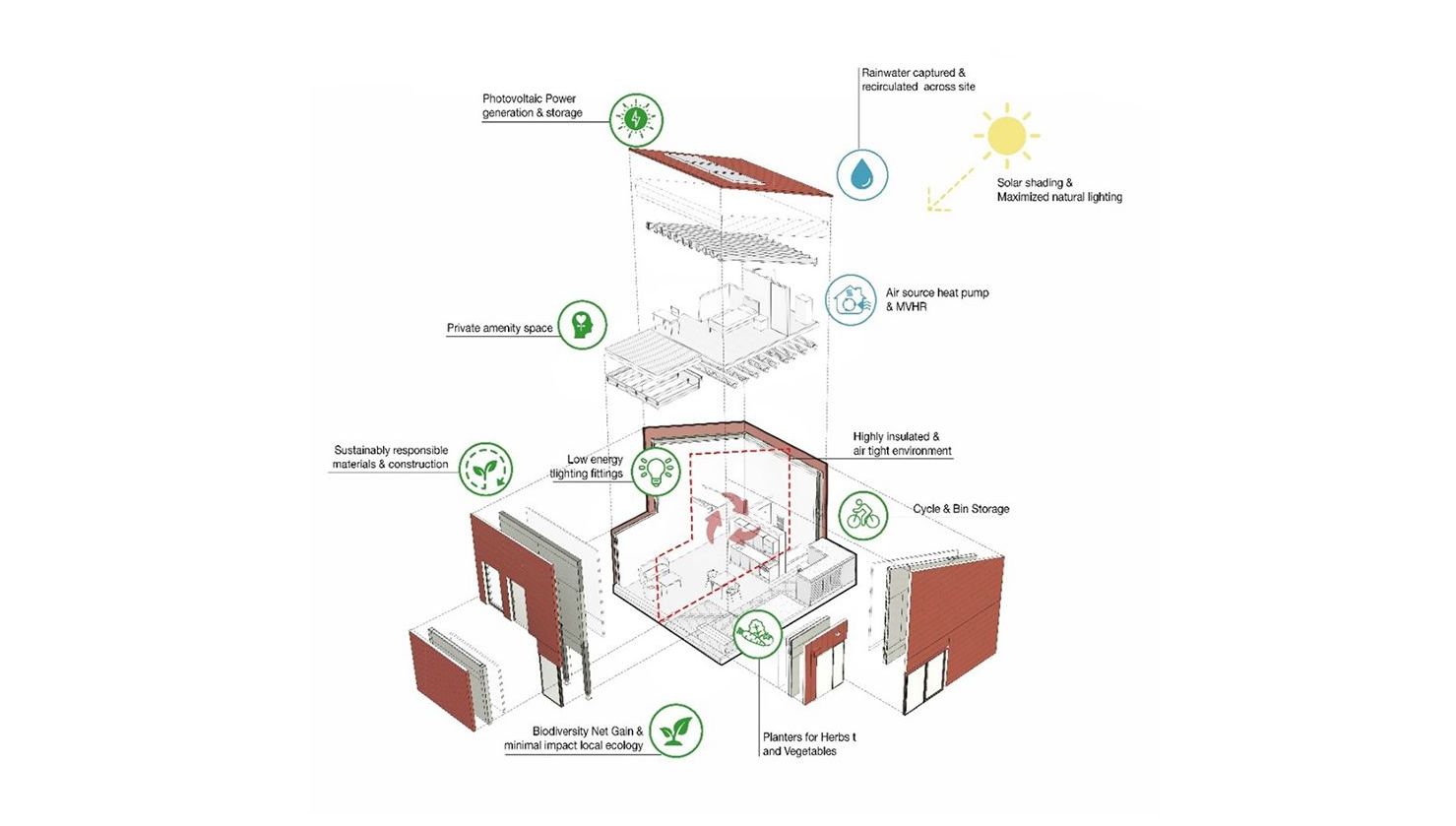

The BDP multidisciplinary design features an open-plan kitchen and living area with a bathroom on the ground floor, and a light-filled bedroom with generous storage above. Expansive windows bring in abundant natural light, enhancing the sense of space while exceeding national standards for a one-bedroom home. Designed with flexibility in mind, the layout can easily adapt for temporary accommodation, downsized living, or small-site infill development.

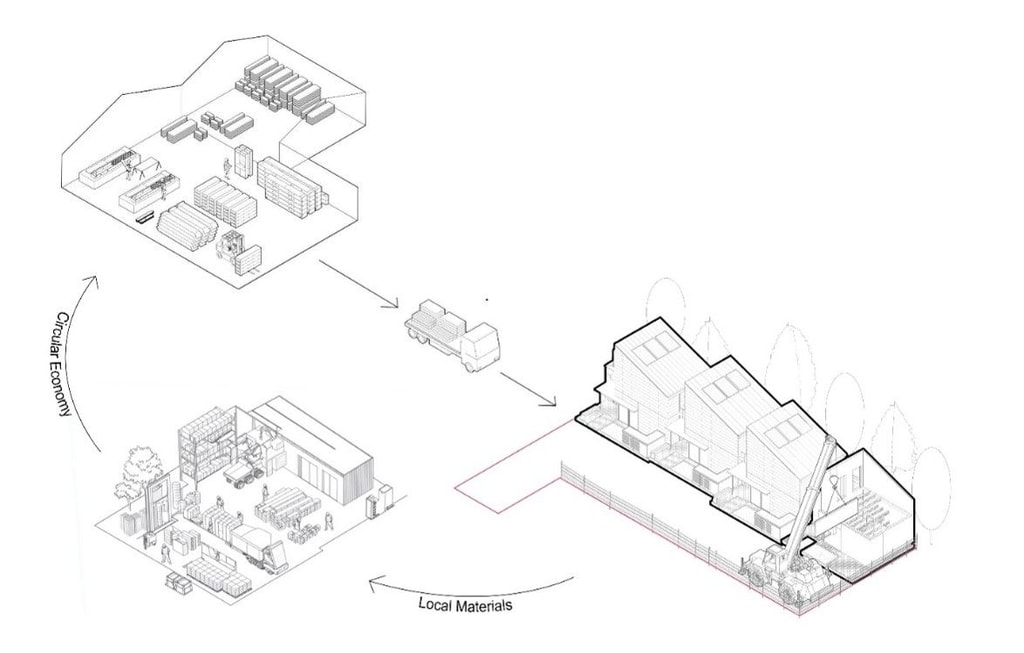

Each home is precision-engineered using advanced digital design and modern methods of construction (MMC). Built under high-tech factory conditions, components are delivered to site for rapid assembly, ensuring quality, speed, and minimal disruption. Smart spatial planning and carefully positioned windows maintain privacy while encouraging a sense of community through active frontages and welcoming entrances. Low-energy systems and integrated design details maximise comfort and efficiency.

A key innovation of the Bell Close project lies in its use of large-format Structural Insulated Panels (SIPs), up to six metres long. This approach enabled the superstructure of each home to be completed in just five days—transforming the construction process on a constrained urban site.

The project also embraced a full Design for Manufacture and Assembly (DfMA) approach. Every element was digitally modelled for seamless production, transport, and installation, reducing material waste and ensuring exceptional build quality. The result is a new model for sustainable, space-efficient living—combining design excellence with environmental responsibility.

The Gap House concept proves that small, low-carbon, innovative homes aren’t just possible, they’re essential. The real conversation now is about what’s next: scaling MMC adoption, creating adaptable homes for diverse communities, and unlocking the hidden potential of small sites across the UK. By focusing on innovation, collaboration, and sustainability, we can transform urban housing from a challenge into an opportunity.

BELL CLOSE: Innovation in Practice

Through this Innovation in Practice report you can hear the story of the Gap House, largely in the voice of key members of the project team.

This purposeful and collaborative report, explores what works and what doesn’t, and identifies opportunities for improvement for the benefit of future projects and the wider social housing ecosystem.

Awards

- 2025 Bristol Property Awards: Transformation Award Win